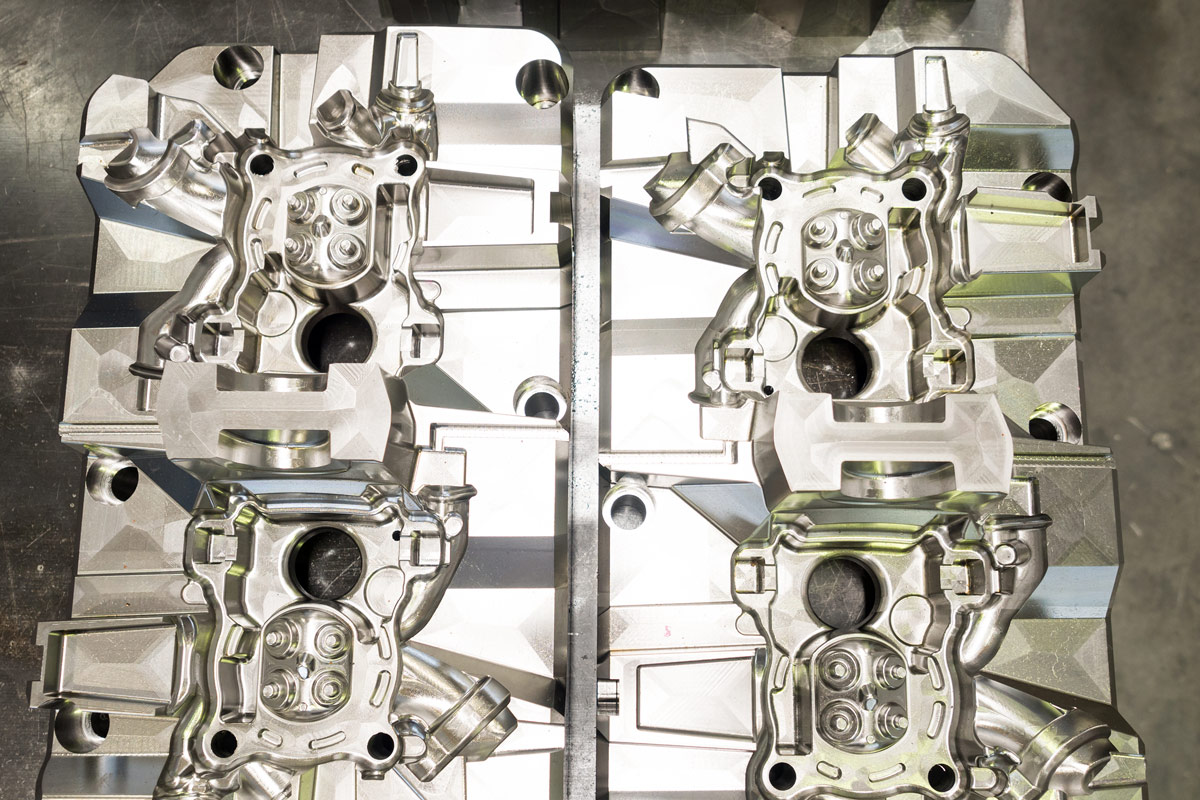

Whether PET bottle, car headlight or medical packaging – precisely shaped plastics are produced in molds made of high-grade steel. At NPE 2018 (stand S15037, Expo hall, level 1) SCHMOLZ + BICKENBACH USA is showcasing innovations and established solutions of the mold steels from Deutsche Edelstahlwerke (DEW) and from Finkl Steel. The application-specific materials manufactured by the subsidiaries of the SCHMOLZ + BICKENBACH Group are extremely resistant to corrosion, very easy to polish, easy to machine and wear resistant, depending on the material.

At NPE 2018, one of the main focuses will be on an innovation from Finkl Steel. The patent-pending, pre-hardened mold steel Corebloc® was engineered for the core plate of injection molds up to 40″ (1015 mm) in size as well as for injection molding tools. The special steel is characterized by excellent through-hardenability compared to standard materials such as 4140 and 1.2312. Machinability and resistance to wear are also outstanding. Corebloc® is suitable for laser-hardening, chrome-plating and nitriding. Users profit from all around cost savings on core side molds and tools. The plastic mold steel MD®-Xtra SH (Super Hard) from the Finkl Steel portfolio will also be presented. Microalloying additions ensure higher hardness levels than standardly available material. With a hardness of up to 43 HRC, the wear resistance is significantly increased. Polishability is guaranteed up to 1200 grit. MD-Xtra SH is ideal for manufacturing sophisticated automotive components with extremely smooth surfaces. Its remelted counterpart, MLQ®-Xtra, combines these benefits with a guaranteed SPI A1 finish because of its premium quality.

“All Stainless”

Bringing out the shine in plastic mold manufacturing – this is the motto of this year’s trade fair launch of the extremely corrosion-resistant, hardened high-grade steel Formadur® PH X Superclean from DEW. With its excellent polishability, it is an ideal solution for manufacturing reflector and lens molds. Formadur® 2083 Superclean from DEW is also known for good polishability and resistance to corrosion. Thanks to its wear resistance, it is ideal for PVC extrusion tools and smaller cross section injection molds. SCHMOLZ + BICKENBACH will also feature Corroplast® FM from DEW at NPE, a material engineered for sophisticated plastic mold bases. This free machining pre-hardened stainless steel has outstanding machining characteristics and dimensional stability.

The tool steels of the SCHMOLZ + BICKENBACH Group are in stock at SCHMOLZ + BICKENBACH USA and SCHMOLZ + BICKENBACH Canada. Customers also benefit from a full range of machining processes, including squaring, chamfering, lifting eyebolts and basic pocket work, vacuum heat treatment as well as metallurgical lab services.