Melting, forging, heat-treating and machining capability at Finkl Steel Co. allows for a wide range of custom-forged products. Multi-diameter shafts, gear blanks, mandrel-forged rings, roll-shells and specialized shapes, including bored products, are available in a wide range of sizes and weights ranging from a few pounds to over 100,000 pounds. Most popular carbon and alloy AISI/SAE grades such as 1026, 1045, 4140, 4150F (Resulfurized), 4340, and 8620 are readily available. Custom and specialized alloys can be considered for melting. Finkl is capable of producing to various industry specifications such as ASTM, API, ASME, ABS, AMS and Military, as well as product-specific specifications. Full laboratory capability and metallurgical assistance is available.

About Finkl Steel®

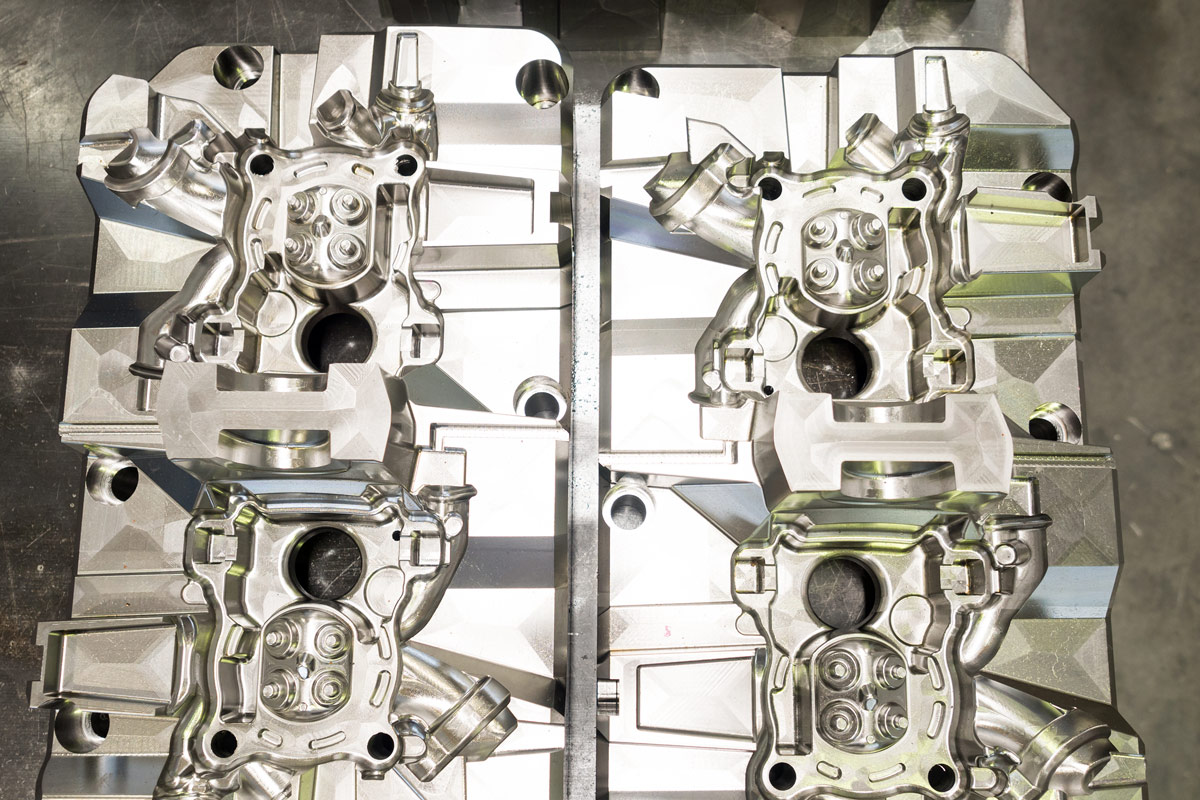

Finkl Steel® is the world’s leading supplier of forging die steels, plastic mold steels, die casting tool steels and custom open-die forgings, processing over 200,000 tons of steel each year. Our products are manufactured at four production facilities in Chicago, Detroit, Houston and Quebec. With more than 100 patents, Finkl Steel® sets worldwide standards including being the first steel manufacturer in America to receive ISO 9001 certification.

Finkl Steel® and Finkl Steel Companies refer to the following entities:

Finkl Steel – Chicago •• Finkl Steel – Sorel

Finkl Steel – Composite •• Finkl Steel – Houston

- Products

- Products MegaMenu

-

- Applications

- Applications MegaMenu

-

- Services

- Partners

- Off-Cut Store

- About

- Careers

- Contact

- Login ButtonLOG IN

Trouble logging in? Contact support at

[email protected].

LOG IN

Trouble logging in? Contact support at

[email protected].