The Finkl Steel Group melts and manufactures steel products from a few pounds to over 100,000. One group, two melts shops, three forging facilities and four production locations build on a tradition of progress and quality.

Melting

Finkl’s high quality steel starts with strictly controlled scrap metal, which is melted using the Electrical Arc Furnaces located in Chicago, Illinois and Sorel, Canada. Further refining takes places in the Ladle Metallurgy Furnaces followed by Vacuum Degassing. An additional melting process, called Vacuum Arc Remelting, produces premium quality material for the strictest applications.

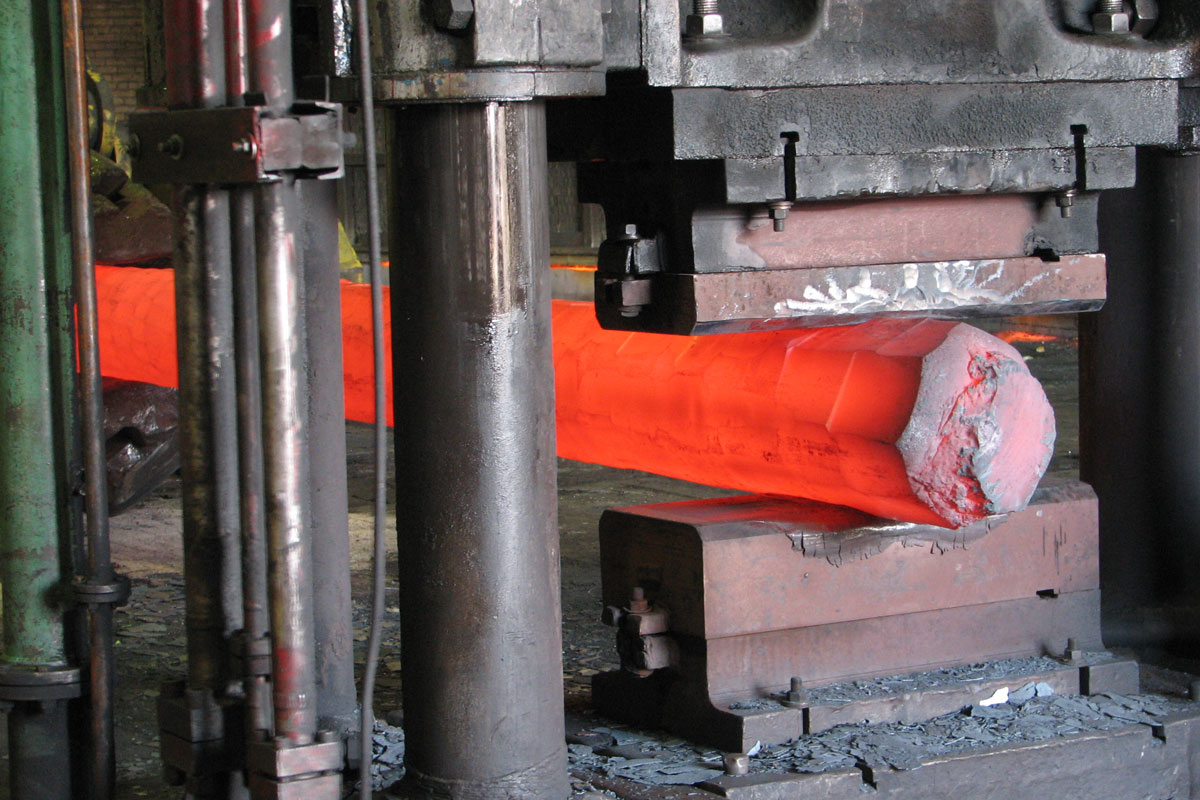

Forging

Finkl Steel began as a small blacksmith shop, steadily increasing in size and technology to become the open die forging leader it is today. With press sizes ranging from 750 tons to 8,000 tons, Finkl produces a wide range of wrought products using wide die technology.

Heat Treatment

Built on William Finkl’s pioneering work on water-quenching steels, the Finkl facilities are capable of heat treating a variety of shapes and sizes to impart maximum through-hardness. Specially designed furnaces ensure efficient, even heating with minimal loss of energy.

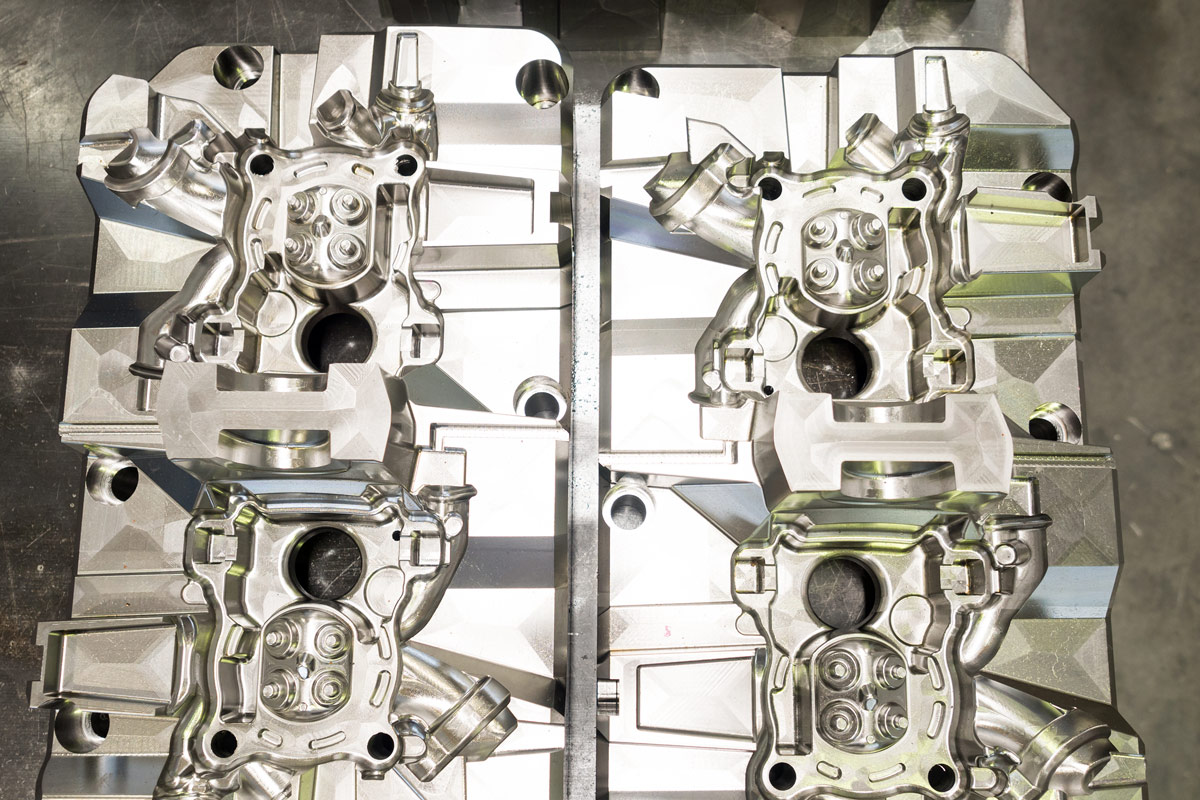

Machining

Milling, sawing and turning machines cut through the scaly, as-forged layer of steel to reveal rough finished surfaces ready for ultrasonic inspection and further machining by our customers.

Value Added

Semi-finished machining, stress relieving, handling holes and shank drawing can all be performed in-house, saving valuable time by delivering ready-to-finish dies and molds.